Top 5 Most Innovative Building Materials

After a grueling albeit extremely fun few months of cranking out eleven new products to debut at ICFF 2016, the (saw)dust has finally settled and we're on track to begin the experimentation stage of design. We've always done things a little differently at Thislexik, so we're super stoked to start playing with new materials. We've been cataloging what feels like hundreds of materials, surfaces, and media from our personal library. Below are a few of our favorites.

Transparent Wood

We recently debuted our Bond Series at ICFF this year, a collection of furniture constructed entirely of UV bonded acrylic. While we originally planned to work with glass in keeping the homage to Shiro Kuramata true to his form, due to the high production costs and issues with being structurally sound because of the size of the pieces, we had to go with acrylic in the end.

While we're happy with the results (and its reception), it was a long and winding process to finalizing the design. With so few options to choose from for the transparent furniture we wanted, it would have been nice to have a more durable, less damaging alternative. Enter the future of transparent wood.

Scientists at the University of Maryland developed a method of stripping the color of blocks of wood, leaving behind a transparent material stronger and more insulating than glass, yet more biodegradable than plastic.

First, scientists strip the color from the wood by placing it in boiling water infused with sodium hydroxide and other chemicals. This process strips the wood of its color, turning it white. The researchers than have to soak the wood with an epoxy which strengthens the wood while making it transparent due to its refractive qualities; the tiny channels that transport nutrients in plants (wood) become conduits of light, allowing it to pass through the solid matter.

There’s already another group of scientists in Sweden who have developed a similar method, so it goes without saying that transparent wood is a definitive product of our future (and hopefully, our future products). With all the strength of opaque and now transparent lumber and its biodegradable properties, this discovery effects a significant shift in the way architects and designers will design for the future.

Leather Made From Pineapple Waste

We've dabbled with leather in the past, but have yet to produce any final products using the animal by-product. Mostly, it's very costly for genuine quality leather and, while we're not against it, we're always looking for more ways to be eco-friendly; our studio leaves little impact on the environment , so we fully support ecologically friendly materials in our designs as well.

So when we heard about the non-woven textile made from pineapple leaves, Pinatex, we were intrigued. Developed by Dr. Carmen Hijosa, the Pinatex fibers are extracted from leaves that are usually discarded after the pineapple process, meaning no additional land, water, or pesticides are needed to produce them.

During this process, called decortication, the pineapple fibers undergo an "industrial process to become a non-woven textile." The resulting roles of fabric can replace traditional animal-based leather and faux leather, both of which involve hazardous chemicals and leave a large carbon footprint.

That's what makes Pinatex the ideal leather replacement; even the by-product of decortication is beneficial to the local farming community as it is biomass which can be recycled as fertilizer back in the pineapple fields, making this a self-sustaining process. And boy, is it beautiful!

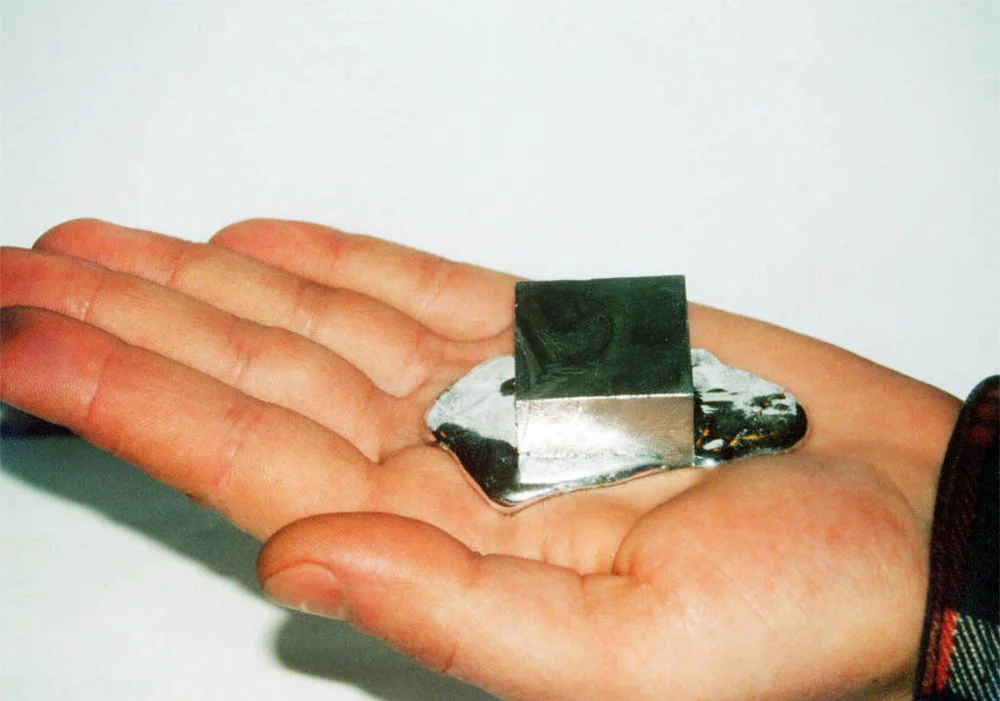

Gallium: Metal that Melts in Your Hand

It may be one of the oldest elements, but lesser known metals. Gallium is a silvery, glass-like, soft metal, with the second largest liquid range of any element and is one of the few metals that melts near room temperature. It doesn't exist freely in nature and must be extracted from flue dusts of coal, or as a byproduct of aluminum and zinc production.

What makes it different from other metals? It clings to or "wets" glasslike surfaces and, like water, it expands when it freezes. Because of its unique properties, gallium has been used as a non-toxic replacement for mercury in telescopes and thermometers, an energy conductor in solar panels, and can be painted on glass to make a brilliantly shiny mirror.

While the majority of gallium's uses have been dedicated to science and technology, there remains an alchemistic pull toward this mystifying metal, one that insists we find new ways to apply these special characteristics in everyday life.

3D Printed Ceramic

3-D printing is all the rage. Heck, we even bought a printer of our own to print in-house. We're printing bricks, genitalia, even food. And while we love the idea that we can cook an entire pizza with the flick of a switch, we think it's even more rad that 3D printing is making it easier to design for the future (not just our rumbling tummies). While additive manufacturing (3D printing) has become somewhat ubiquitous in recent years, ceramics has upped the ante.

Ceramics can withstand an absurd amount of heat and pressure without warping or breaking, making it difficult to 3D print the material in comparison to metals and polymers, which can be fused together by applying heat.

Because ceramics cannot be cast or machined easily, 3D printing enables a big leap in geometrical flexibility. A team at HRL Laboratories in Malibu, California has developed a “pre-ceramic resin,” which can be 3D printed much like regular polymers into complex shapes. The process, known as stereolithography, fuses a powder of silicon carbide ceramics using UV light. Once the basic shape is printed, it can be heat-treated at 1,800°F to transform the pre-ceramic resin into a regular ceramic object.

With fewer limitations on the kinds of materials that can be used, the resulting objects have superior qualities to normal 3D-printed objects. With fewer flaws than their counterparts, they resist cracking for much longer and can withstand far higher temperatures—2,500⁰F is a balmy day at the beach for ceramics while most metals would melt long before reaching that temperature.

3D printing has come a long way since its invention in the 1980s, and the scientists at HRL Laboratories predict the process will only improve, projecting that the technique will have the ability to quickly build new parts that require high heat resistance —like steam turbines, hypersonic vehicles, and jet engines.

Cork: All Around Winner

As far as sustainability goes, cork is difficult to beat. Cork production is generally considered sustainable because the tree from which is comes from is not cut down; only the bark is stripped to harvest the cork, with no harm done to the tree. In fact, with a bare trunk, the tree absorbs three to five times the CO2 to aid the regeneration process, helping us breathe a little easier. So the ecological footprint from cork's extraction to the final product is minimal compared to other building materials.

Because Thislexik is dedicated to eco-friendly practices, a couple of our first designs were made from cork so we'd like to return to the renewable resource to test it's capabilities.

When people talk about cork, the first thing it comes to mind is wine stoppers, but in fact cork is being used for every purpose we can imagine like flooring, walls, furniture, tableware, clothing. Even NASA uses it for the isolation and thermal protection of their space shuttles. The industry is realizing that cork is a very resistant waterproof material and of course eco-friendly since its extraction doesn’t harm trees. So all these attributes take cork to another level of importance for every kind of application.

Basically, cork is awesome.